Titan Timbers Glue Laminated Columns

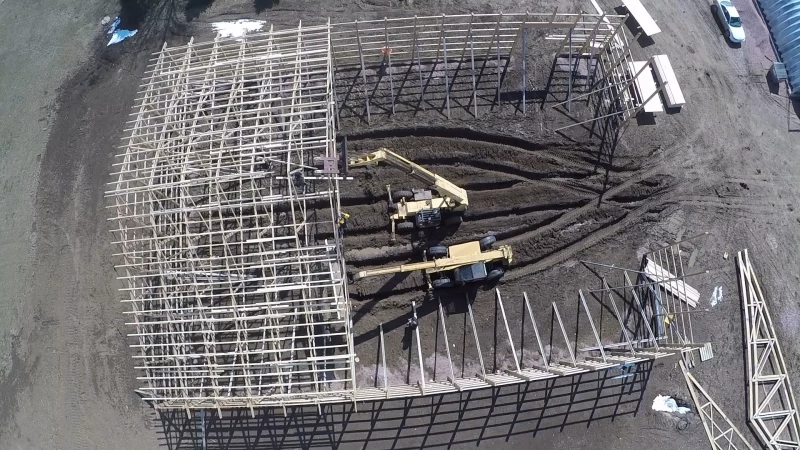

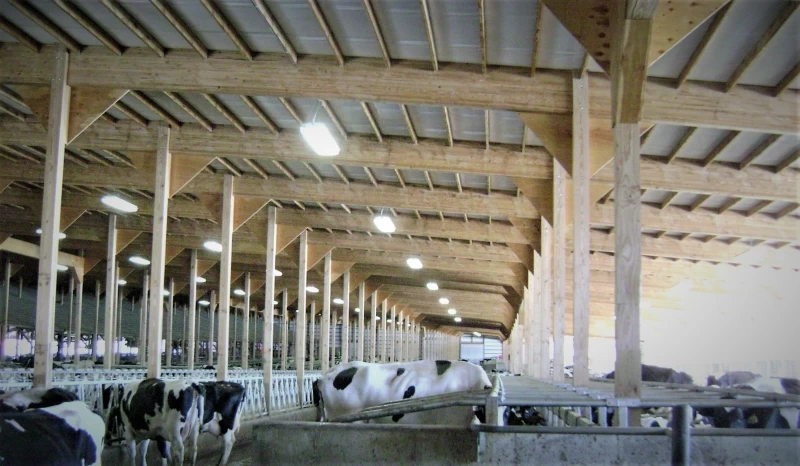

Why Titan Timbers are the best choice for your next Post-frame project?

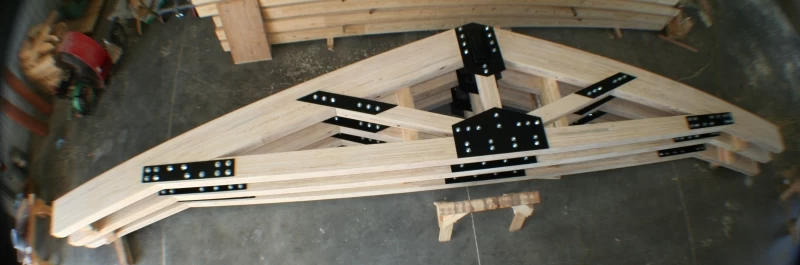

Titan Timbers glue laminated wood columns use #1 SYP (Southern Yellow Pine) lowers for their superior treatability. Permanent two-part Loctite® Purebond GT adhesive is cured in a high-temperature beam press and total face gluing resists individual ply separation, assuring that every column withstands warping and twisting, and are 100% usable on the job site. Mechanical fasteners (nails) are not needed to secure Titan Timber Glue laminated columns. Stringent quality control and grading standards are monitored by AITC, our third-party inspector. This process gives Titan Timbers® dimensional stability that solid sawn timber and mechanically nailed columns don’t have.

Finger Joints

1” structural finger joints, utilizing melamine adhesive that conforms to ASTM 2559, was developed for added strength to Titan Timbers. It’s important to understand that if an adhesive does not conform to this standard, it is NOT a structural finger joint.

About Nail Lams

Nailed and glued columns are simply nailed lumber. Liquid Nails®, Great Stuff™, Super Glue®, Duct Tape®, etc are not structural glue. Its sole purpose is to eliminate see-through gaps in the nailed boards. If you are currently using nail lams, ask your supplier for their daily destructive, quality control test analysis. If they share this with you, make a comparison with our strength charts below. If they decline, then ask yourself, “Why am I considering nail lams?”. Our manufacturing process allows us to laminate columns and beams up to 30 plys! Try that with a nail lam!

On Hand Inventory

We have a full line of inventory available for prompt shipment of Standard 6’ minimum treated Stock.

- 3ply 2 x 6 - 16’ to 36’

- 4ply 2 x 6 - 18’ to 36’

- 3ply 2 x 8 - 20’ to 36’

- 4ply 2 x 8 - 22’ to 38’